ALUMINUM EXTRUSION SOLUTIONS

When the demands of your product exceed what "status quo" meets.

Expertise and technology to address your unique requirements and needs from highly engineered design to secondary operations to packaging and distribution.

Enhance Your Manufacturability

Our experts will work with you and assess how you can take your products to the next level. We'll find ways to remove non-value added activities and handle your most demanding extrusion requirements.

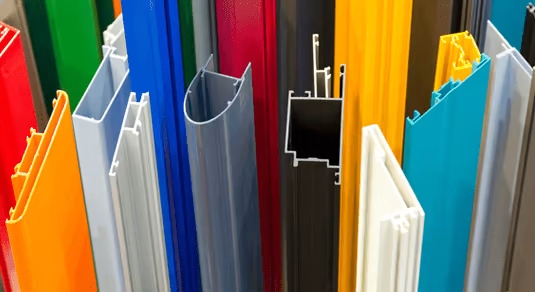

Browse Our Profiles

Check out our catalog of profiles. We offer several different lines of aluminum extrusion profiles from our special industrial line, heatsinks, channels, Z-bars, frame/edge, floor, truck curtain tablets, dry vans, and shade profiles.

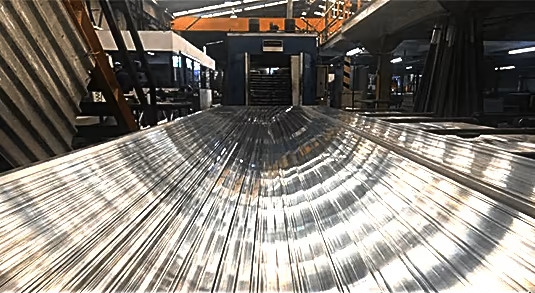

Capacity to Meet Your Needs

Plant #1

- Spanish Manufacturing

- 1600 Ton

- 6″ Ingot Diameter

- 7″ Outlet

- Cooling table 45 linear meters with cooling system

- Automated puller

- Double cradle press at die change

- Hydraulic circuits controlled by PLC

- Fully automated press.

Plant #2

- Korean Manufacturing

- 1800 ton

- 7″ Ingot diameter

- 8″ Outlet

- Cooling table 40 linear meters with cooling system

- Automated puller

- Double cradle press at die change

- PLC Controlled hydraulic circuits

- Fully automated press

Plant #3

- Italian Manufacturing

- 2200 Ton

- 8″ Ingot diameter

- 11″ Outlet

- Cooling table 70 linear meters with automated water-air system

- Double puller with saw cut on the fly

- Heat treatment furnace 24 meters long

- Double cradle press at die change

- Hydraulic circuits controlled by PLC

- Fully automated press, auxiliary equipment and stocker.

Treatment and Fabrication

Alloys and Tempering

We can readily provide a selection of alloys. We have 6061, 6063, 6005, 6105, and other alloys available upon request.

We can treat your alloy to the desired tempering. TF, T1, T52, T5, T6 are some of the options we provide.

Extrusion Fabrication

Going beyond extrusion, we can offer the following services:

- Cut to length

- Mitering

- Custom CNC Machining

- Drilling, Tapping, and Counter-Sinking

Surface Finishing

Choose from a wide array of options to get what you need:

- Anodizing

- Matte

- Glossy

- Powder Coating

- Painting

Custom solutions

We provide custom extrusion design and manufacturing. You bring the idea, we make it.

Tailor-made dies

We're ready to help you develop the most cost-effective and optimal design for your product.

Surface treatment

Strengthen your aluminum extrusions and add a finish that enhances the appearance.

Quality expertise

Our team understands the importance of quality in delivering high-value products.