Stamping, a versatile manufacturing process, plays a crucial role in shaping metals to create a myriad of components. From simple to intricate designs, stamping is a cost-effective and efficient method widely utilized across various industries. Let’s delve into the world of stamping and explore how this technique contributes to the manufacturing landscape.

The Basics of Stamping:

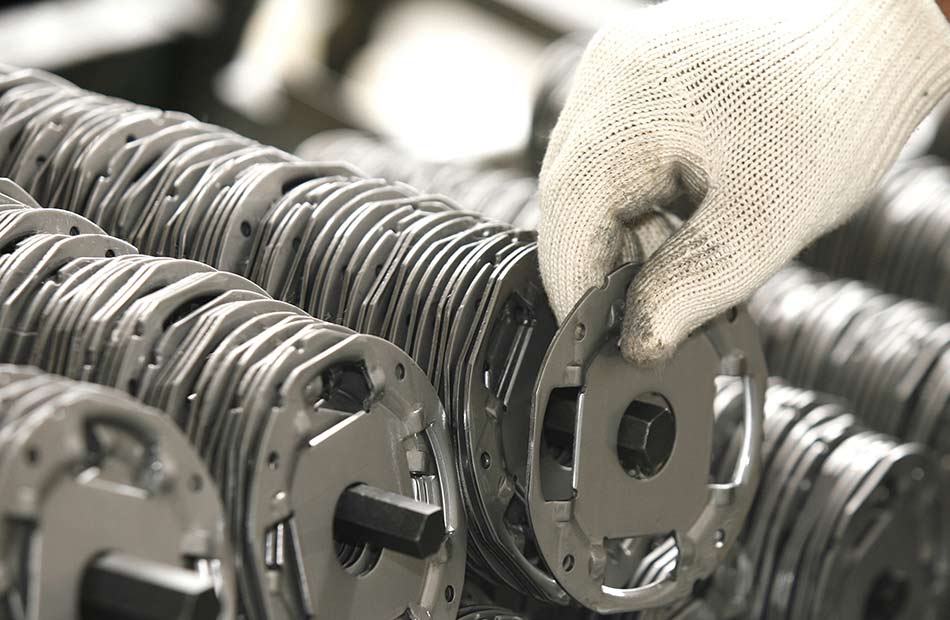

At its core, stamping involves the use of a press machine and a die to transform flat sheet metal into desired shapes. The process encompasses several techniques, including punching, blanking, bending, coining, embossing, and flanging. Each technique serves a unique purpose, offering manufacturers the flexibility to craft a diverse range of parts.

Efficiency in Production:

One of the primary advantages of stamping is its efficiency in high-volume production. Once the tooling is in place, the process becomes remarkably swift, with large quantities of parts being manufactured quickly and consistently. This efficiency not only reduces production time but also lowers the cost per part, making stamping an economically viable choice for mass production.

Consistent Quality:

Stamping ensures consistent quality across all produced parts. The use of precise dies and molds guarantees uniformity, meeting stringent specifications and maintaining high-quality standards. This reliability in producing identical parts is paramount for industries where precision is non-negotiable.

Versatility in Materials:

Stamping is not limited to a specific type of metal; it accommodates a wide range of materials, including stainless steel, aluminum, and various steel grades and alloys. This versatility allows manufacturers to choose the material that best suits the requirements of the intended application, enhancing the functionality and durability of the stamped parts.

Cost-Effectiveness:

Stamping stands out as a cost-effective manufacturing solution. Once the initial tooling is set up, the cost per stamped part decreases significantly. This affordability makes it an attractive option for businesses looking to optimize their production processes without compromising on quality.

Conclusion:

Stamping in manufacturing is a true testament to the marriage of efficiency, precision, and versatility. Whether creating intricate components or large quantities of simple parts, stamping remains a go-to method for many industries. Its ability to offer cost-effective, high-quality solutions ensures that stamping will continue to be a cornerstone of modern manufacturing processes.